Measurement & Control Systems

SmartFillIn order to optimise grinding processes it is necessary to measure the most important parameter – the fill level – as precisely as possible. This key parameter cannot be measured directly it needs to be determined by acoustic or vibration measurement due to the obvious disadvantages previous measuring methods (like microphones) are quite useless for nowadays needs. Due to measuring the sound directly where it occurs (on the mill shell) all these disadvantages can be avoided.

The solution is SmartFillTM – a fail safe, high precision fill level and temperature measurement system for ball mills.

High precision measurement of fill levels:

- easy installation

- zero crosstalk

- free frequency band

- almost no maintenance

- process interface (4—20 mA)

- up to 3 sensors of free choice

- up to 16 product types

- industrial proved: IP65 / Atex

- mill mounted (self-powered)

Using a high level control achieves a return of investment in less than a single year.

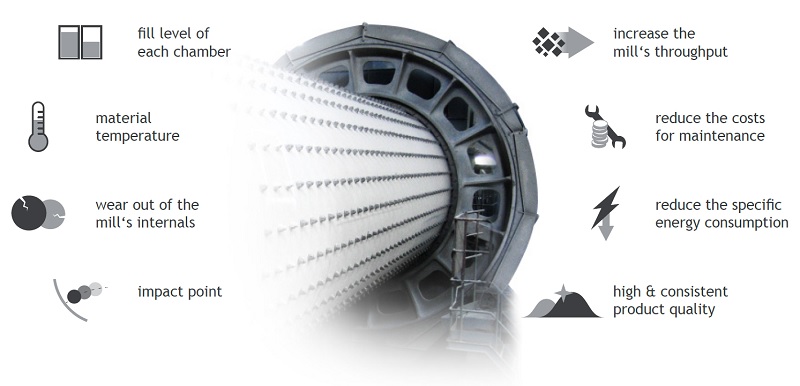

How SmartFill improves your production process

Incorporating the precise results into your grinding process is directly improving your production process. In order to achieve this improvement you permanently need to adjust the mill’s feed. While keeping the fill level at the optimum the grinding process becomes stable.

A good operator, for example, take care of the fill level and manually changes the fresh feed.

Using an automatic controller provides you with even more advantages and convenience. Automatic control reliably compensates disturbances like strong differences in raw material quality and prevents overfilling. These advantages are based on a fact. The automatic controller is reacting fast and precise on concurrent events, taking the correct decision at any time.

In addition you achieve a high product homogeneity ensuring an increased product quality.

SmartFill’s range of application:

All kinds of industrial ball mills or grinding of:

- cement

- limestone

- coal

- gold ore

- iron ore

- aluminium oxyde