Conveying

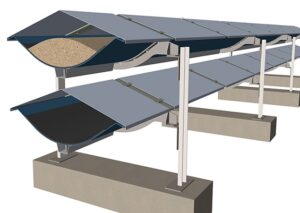

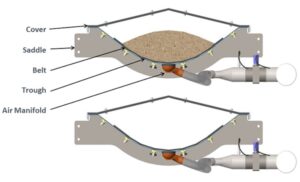

The Belt ConveyorBruks Siwertell have innovatively combined the use of air-cushion technology with their standard belt conveyors to create The Belt Conveyor.

You can now benefit from a high capacity conveying system that offers minimal equipment wear and very low operating costs as a result of reduced friction in the conveying line.

Like the Tubulator, the air-supported belt conveyor has a totally enclosed design that protects the environment from dust emissions and reduces any material losses to a minium.

Rather than using a pipe as the key containment method, The Belt Conveyor uses a formed pan to support the belt with a fully flanged cover over it to make it dust tight. The belt can comfortably conform to the profile provided by the pan without the added stretching needed to travel through a pipe.

The shape of the pan also mimics the geometry of a 35 degree idler conveyor but without the rollers.

The Bruks Siwertell air supported belt conveyor offers an extremely smooth ride surface, eliminating the bumpiness characterised by traditional idler supported belt conveyors. Therefore material is discharged in exactly the same condition as when it was loaded onto the belt.

Idler belt conveyors have rollers spaced at 1.2m intervals generating movement in the belt. The shaking that occurs over any distance encourages smaller particles to sift between larger ones, stratifying the load on the belt, which can have a significant impact on many downstream processes.

By the time material is discharged off the head pulley into the following chute the fines can be heavily concentrated at the surface of the belt making belt cleaning more difficult.

The Bruks Siwertell air-supported belt conveyor eliminates stratification.